Getnow

Groceries for the digital age. Fast, fresh & flexible: how we automated getnow’s online grocery experience

- Client:Getnow

- Year:2018

- Scope:

- Concept design

- UX/UI design

- Backend development

- Android App development

Intro

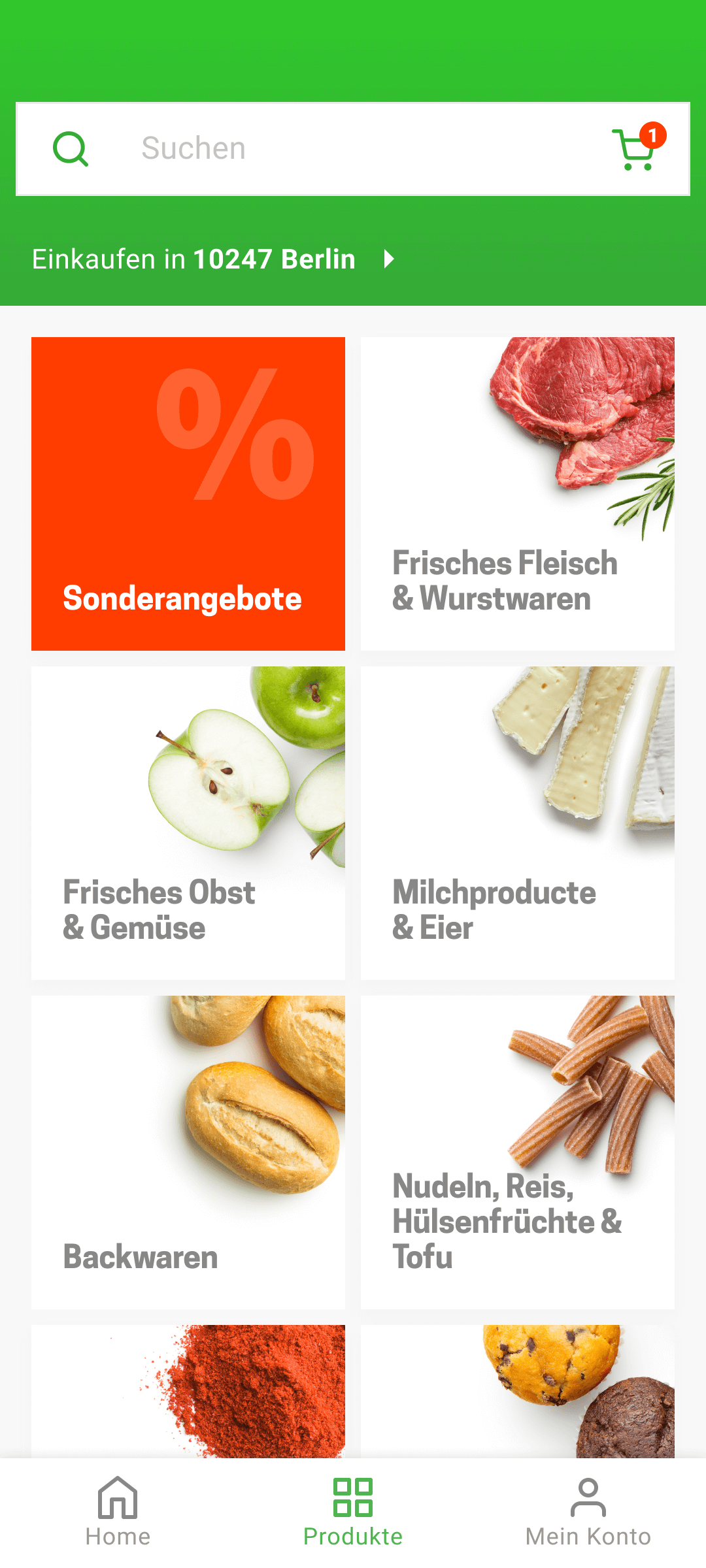

Groceries to go from Germany’s ground-breaking online delivery service

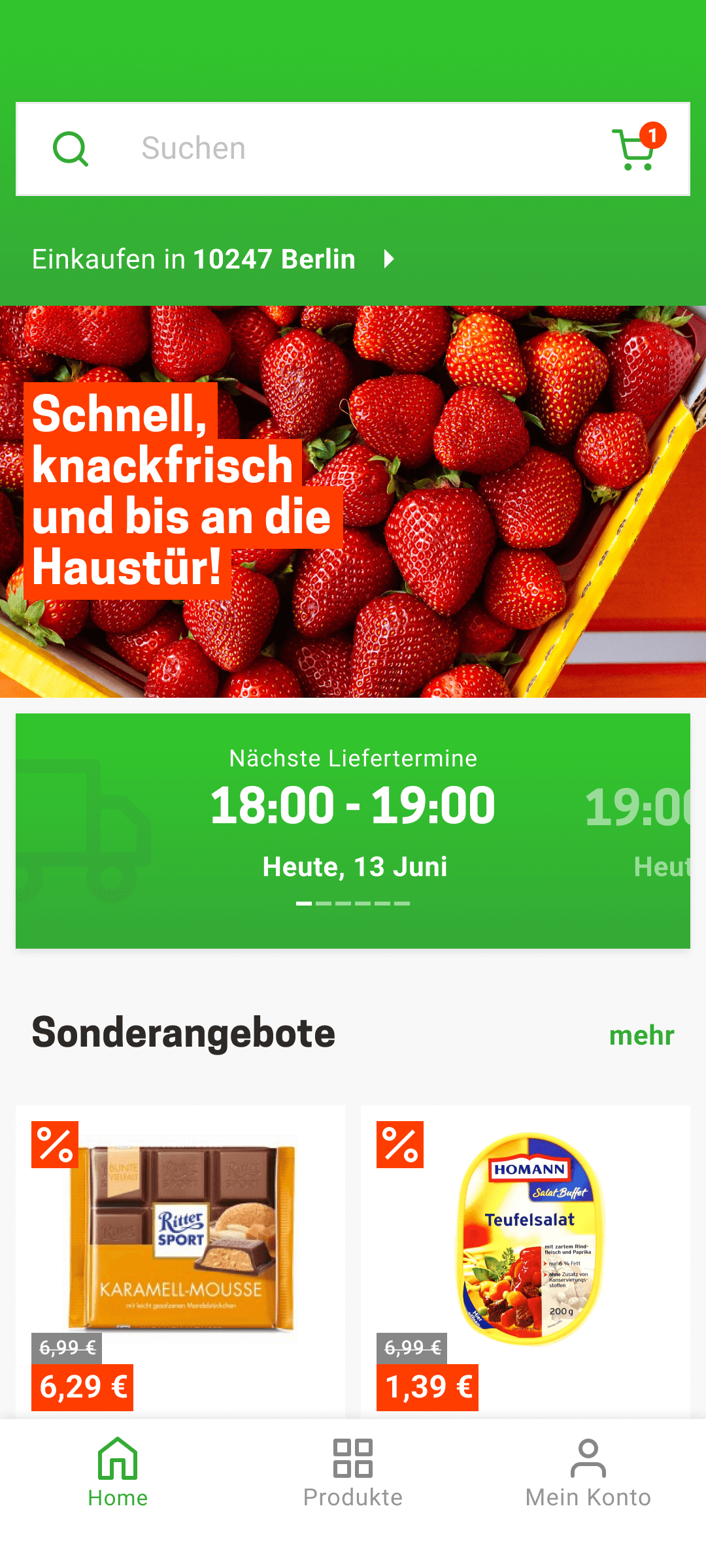

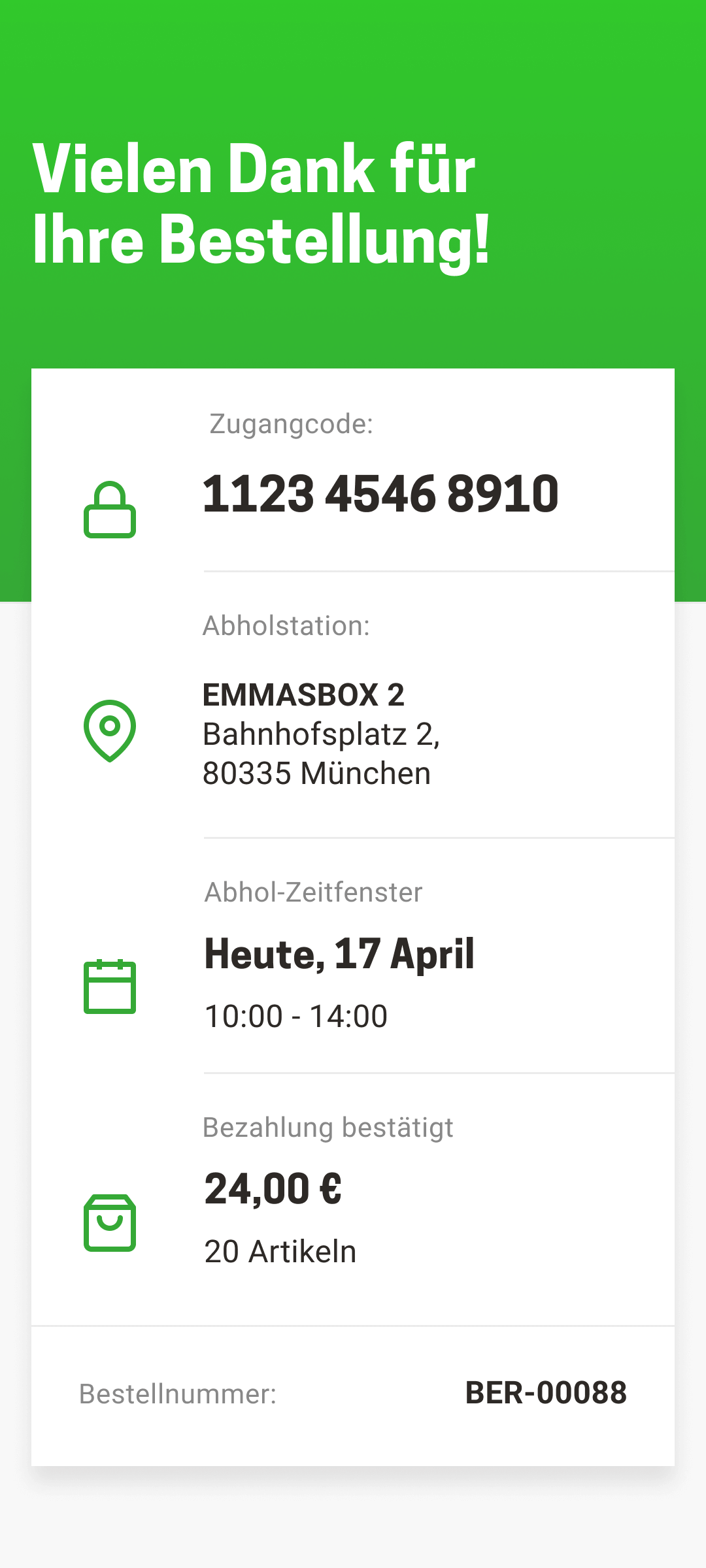

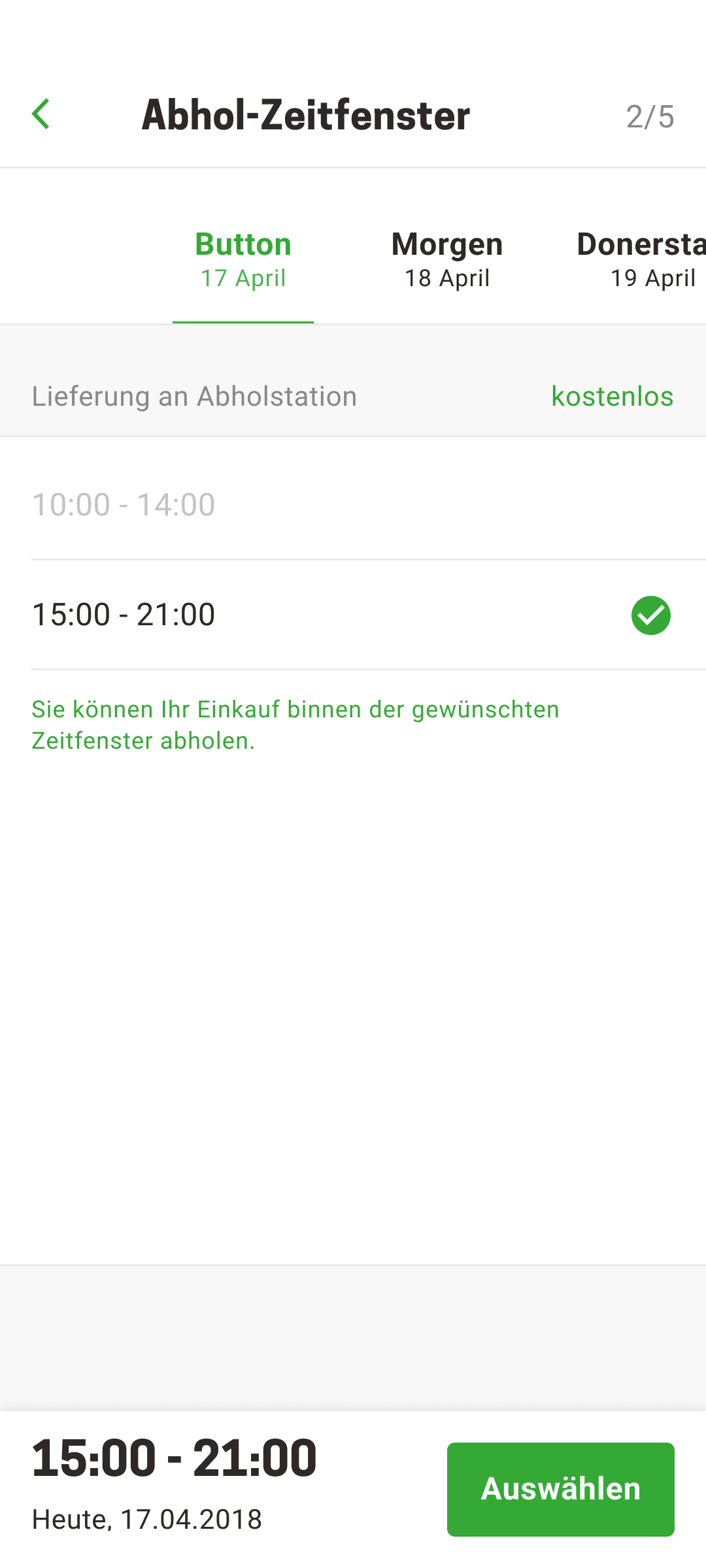

Need milk? Thanks to online grocery pioneer getnow, that satisfying slug of dairy in your coffee is just a few clicks or swipes away. Getnow takes the sting out of the food run by making all aspects of ordering and delivery surprisingly seamless, from product selection to same day front-door delivery, with no minimum order value. As the first and only player, getnow favours an asset-light approach, i. e. the company does not have its own warehouses for stock or its own fleets for deliveries. To make this work, the right technical infrastructure is key for running a successful business and for scaling the operation teams of getnow and the system’s white label users.

The logistics behind it all are equally impressive, both in the supply chain and behind the digital scenes. While chilled and frozen goods require specific storage and transport conditions; payment processes, delivery interfaces and resupply chains come with their very own, unique challenges. Most people looking to avoid the post-work rush and cashier queues have zero idea what it takes to keep this finely tuned machine running – on time and well-stocked, even during periods of spiking demand.

The challenge

How to grow without growing pains

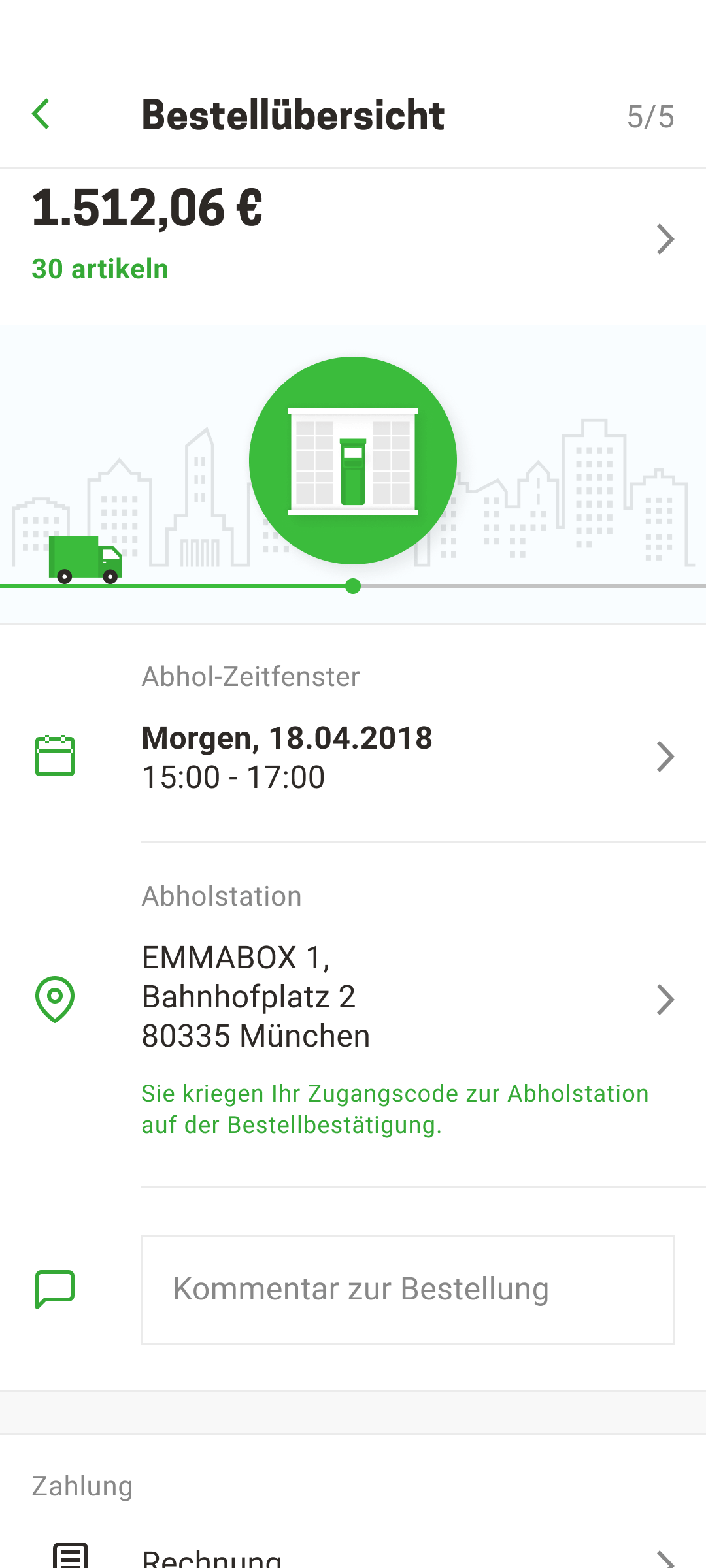

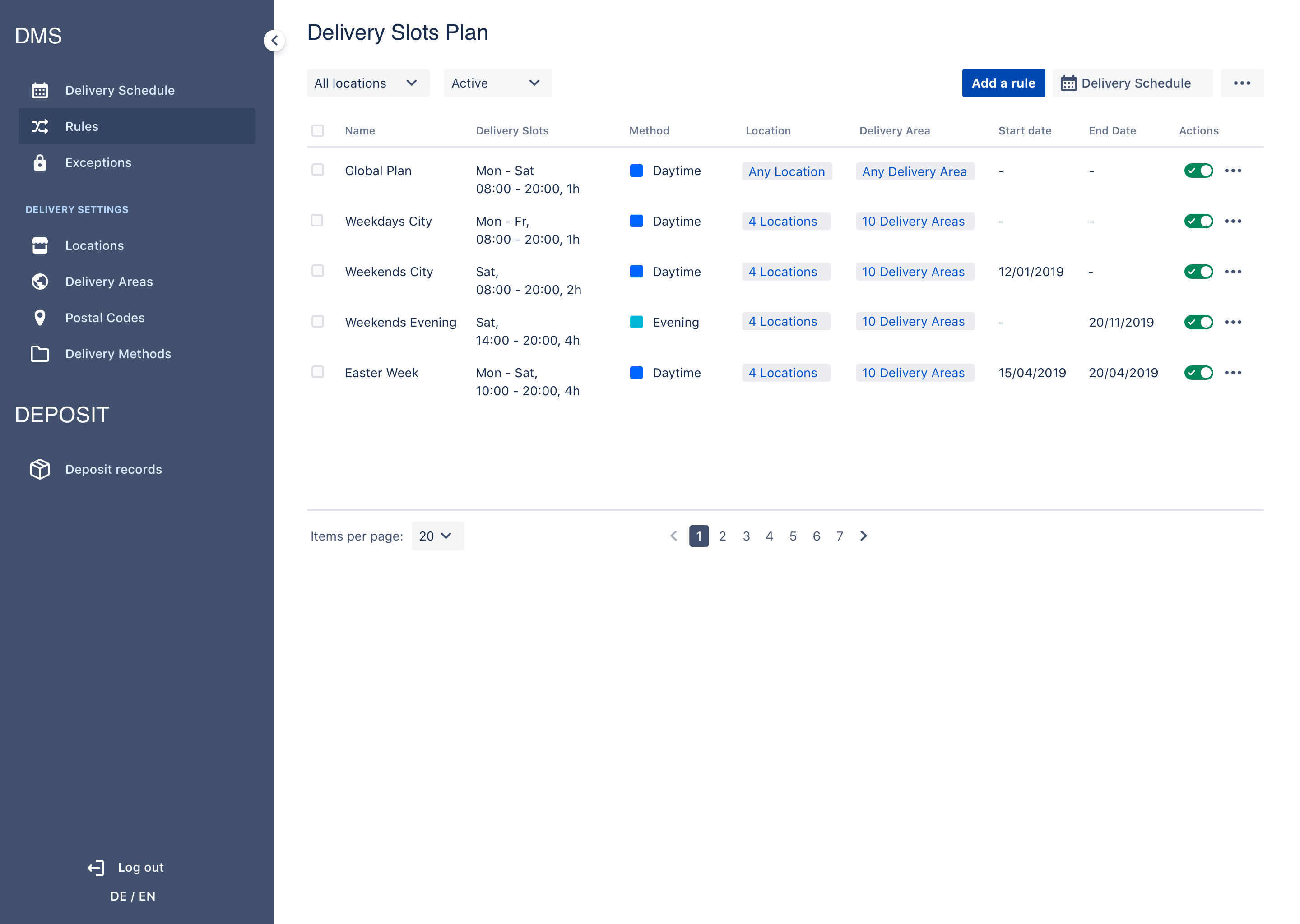

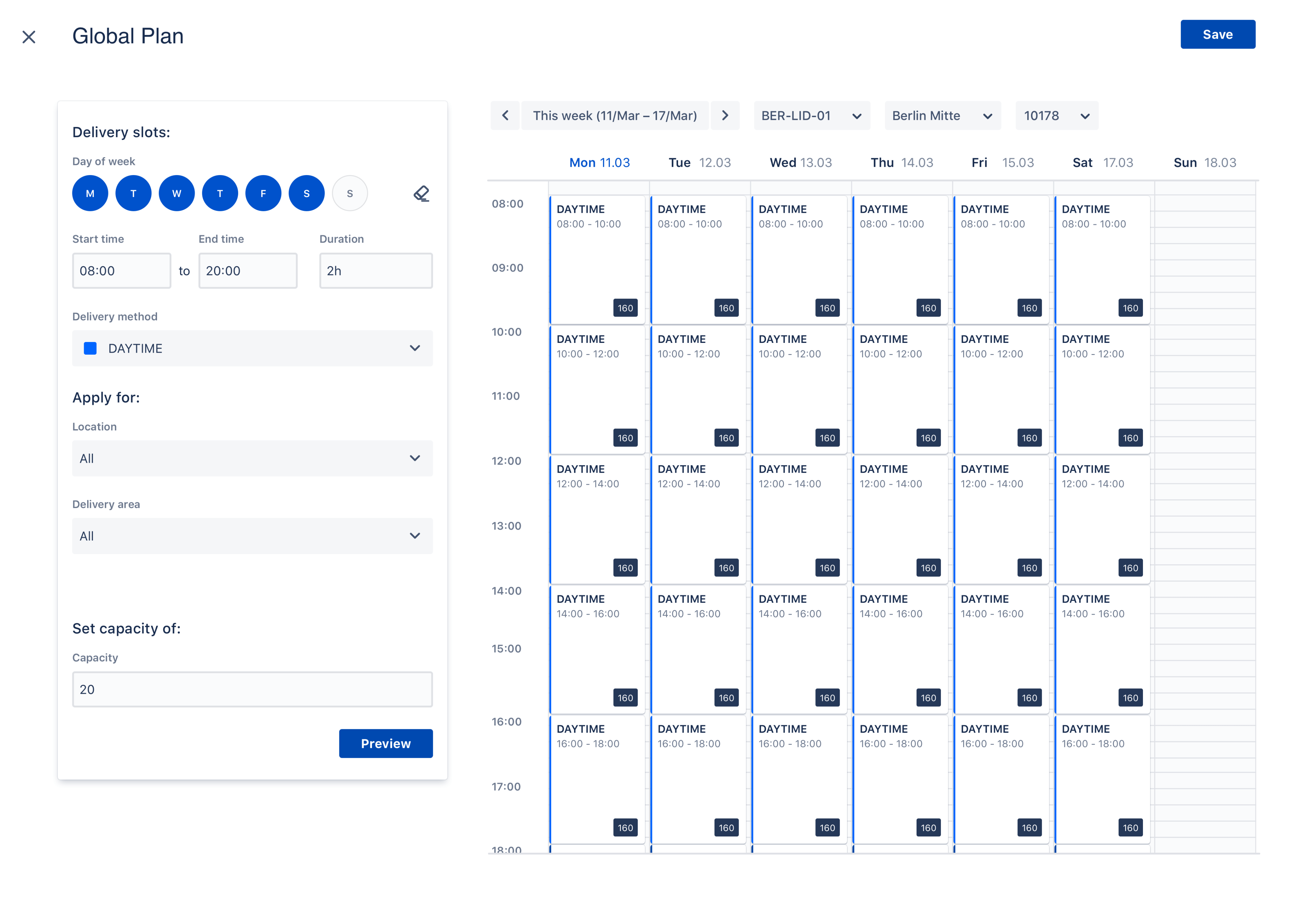

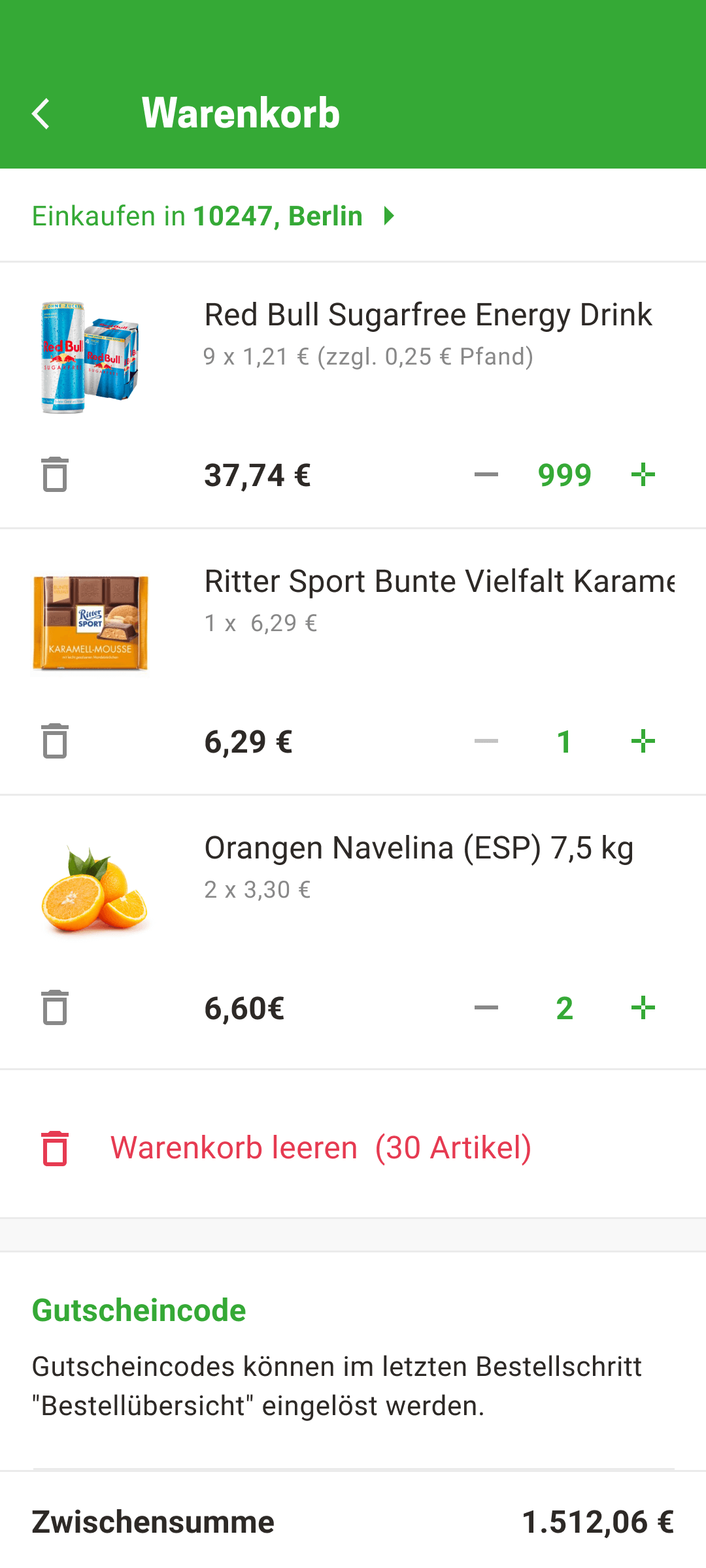

When getnow started out in two German cities, they quickly hit barriers of scale. At the time, the e-commerce platform was not ready to handle rapidly changing product prices and availability while also increasing customer traffic. What they needed was a flexible delivery management system designed to integrate with all aspects of grocery ordering, storage and delivery. The resulting delivery order management system would be the beating heart of the whole company. From order managers and analysts to product pickers and delivery staff: everyone needs it, everyone uses it, everything is built around this one core system. And everything needs to be designed for use in hundreds of different stores. To get it right and avoid future hick-ups (think easily forgotten features like deposits and returns), the old system required a thorough redesign and rebuild from the ground up, optimised for peak performance, excellent internal integration and highly efficient operations.

The process

It’s a marathon, not a sprint

Faced with such a complex integration and development task, we knew it was worth spending time to get it right – and to set the right course for future success. Working extremely closely with getnow’s own Chief Product Officer Dr. Oliver Oechslein, Head of UX/UI Stephanie Friedl and CTO and Managing Director Sebastian Wiese, our team spent approx. 18 months on identifying ways to improve operational capacity through workshops, system thinking and agile methods, building the new backend (Ruby on Rails) to control operational capacity and the order fulfilment process, creating a user-friendly order management front end (React Native) and setting up an Android app compatible with Zebra and Honeywell scanner devices to speed up picking and packing.

The solution

A blueprint for state-of-the-art online shopping

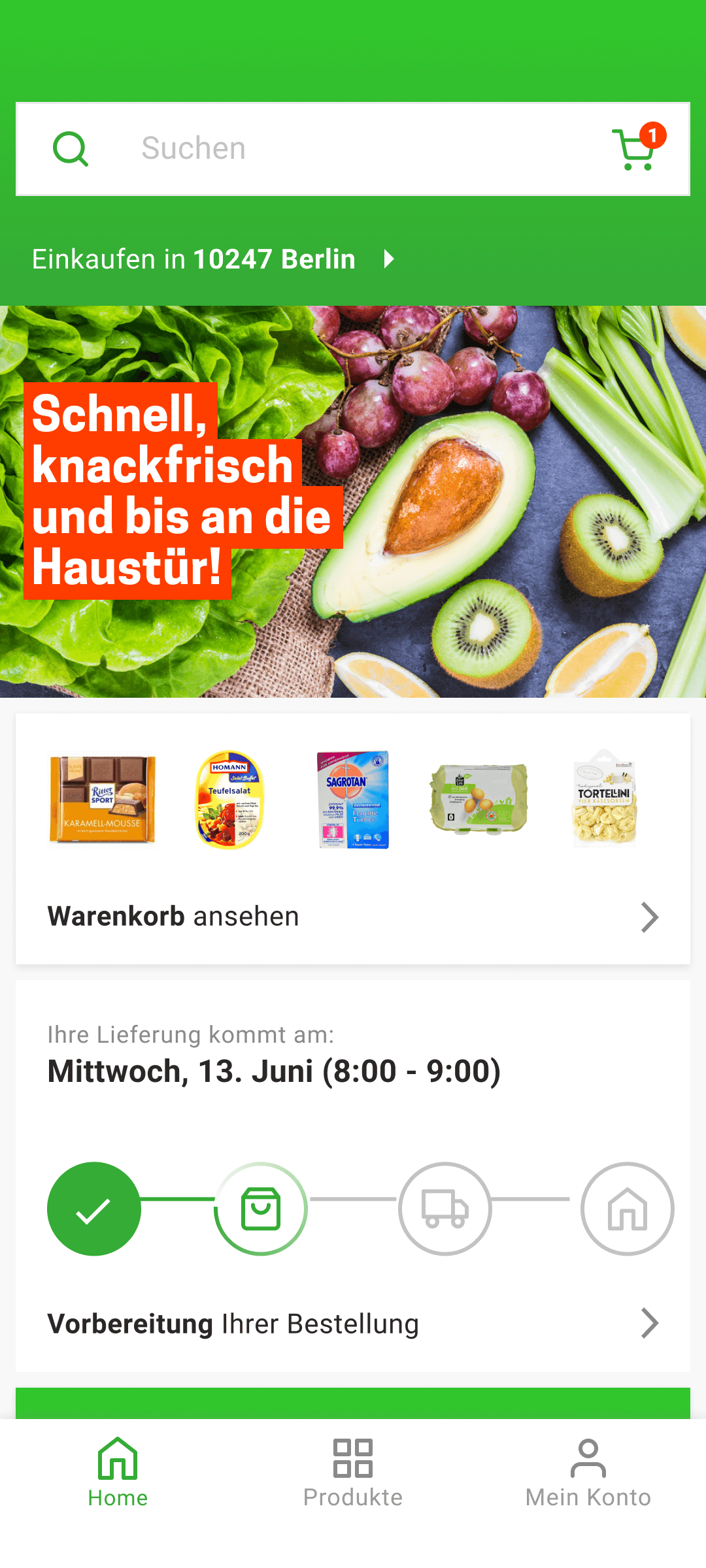

Behind that spontaneous milk order (and delivery) lies a solid software architecture with ample room to grow, scale up and evolve. All functionalities and applications are designed to be modular and connected via API and Microservice architecture. This lets getnow integrate easily into other infrastructures or market the solution to new partners, module by module. To keep everything running smoothly – and ensure a working mum gets her baby’s nappies on time – our engineers developed a secure, scalable and high performing system built to deal with everyday order management and fulfilment as well as more unusual supply chain scenarios. The resulting product became so successful and generated so much value for the company that getnow decided to monetise the software and sell a white label version Globus to other companies.

YND developed backend and frontend of scalable and high-performing order management system

Outcome

“YND helped us unlock new opportunities by redefining our IT ecosystem – working as equals and serving as valued sparring partners. There were no quality trade-offs and a true get-things-done spirit: Everything followed an agile, solution-driven approach. To us, having reliable partners like YND who understand our requirements is vital. By now, the YND team feels more like an internal Getnow team and we really appreciate their commitment and, especially, their speed. This also helps us be fast, which is one of the most important things in our start-up world. We are really looking forward to tackling the next challenges and solutions together.”

Welcome extras

Exploiting the logic of logistics

The benefits of full operational capacity control are obvious. When demand is sky high, too many orders can overtax even the most resilient system. Thanks to real-time regulation options baked into the new delivery management system (DMS), getnow can adjust the number of orders accepted by the system according to demand, delivery capacities and product availability. Naturally, all of these factors are automatically tracked by the system. The result: a system working at 100 % capacity.

Features

The modern way to pick & packs

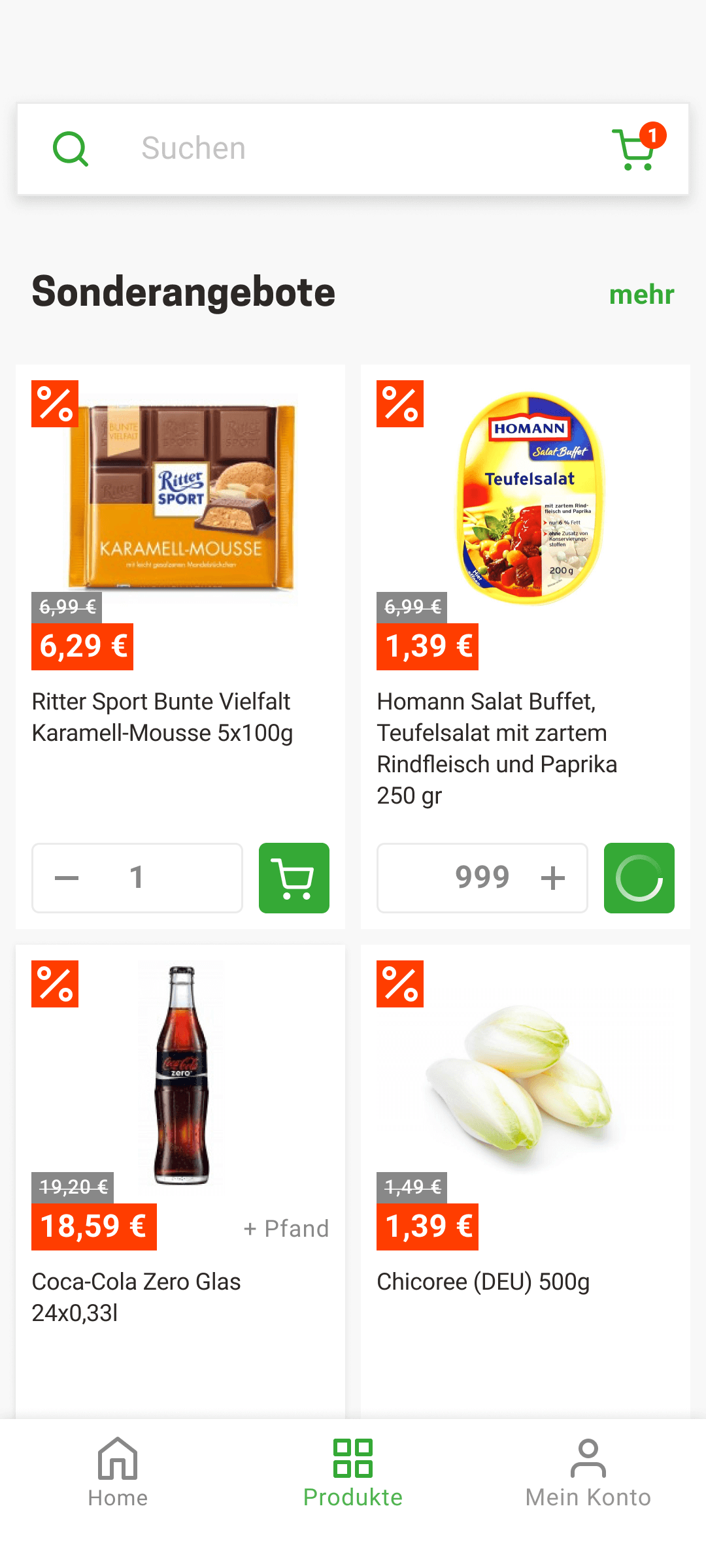

Ditch the paper trail! The handy PnP (pick and pack) app automates order fulfilment by integrating product list, scanner and efficient picking instructions in a single app, thus reducing the picking and packing time of each order by an impressive factor of 3.

Better returns

Prior to our deposit handling solution, returnable bottles could cause surprising bottlenecks in the system since all returns had to be triggered and processed manually. The new set-up automatically tracks deposit-relevant items and processes returns based on the customer’s original order.

Why YND?

They deliver.

And so do we.

There’s a reason why getnow is one of our longest-running clients. Helping getnow grow from the ground up has let us establish a great working relationship based on open, transparent communications. We know how they tick and think, they know they can trust us and rely on us to get things done, no matter the complexity. For us, this is a great example of why it’s really worth developing and cherishing a great client/supplier relationship since it benefits both sides and really elevates the quality of collaboration. A collaboration that continues to thrive and evolve - we can’t wait to see what’s next on the menu for getnow and YND.